To help our client meet product specification and station uptime requirements at a 50 year old 60MMSCFD gas fractionation plant, ZAP engineered a solution to replace the controls system while drastically minimizing production outages during the upgrade.

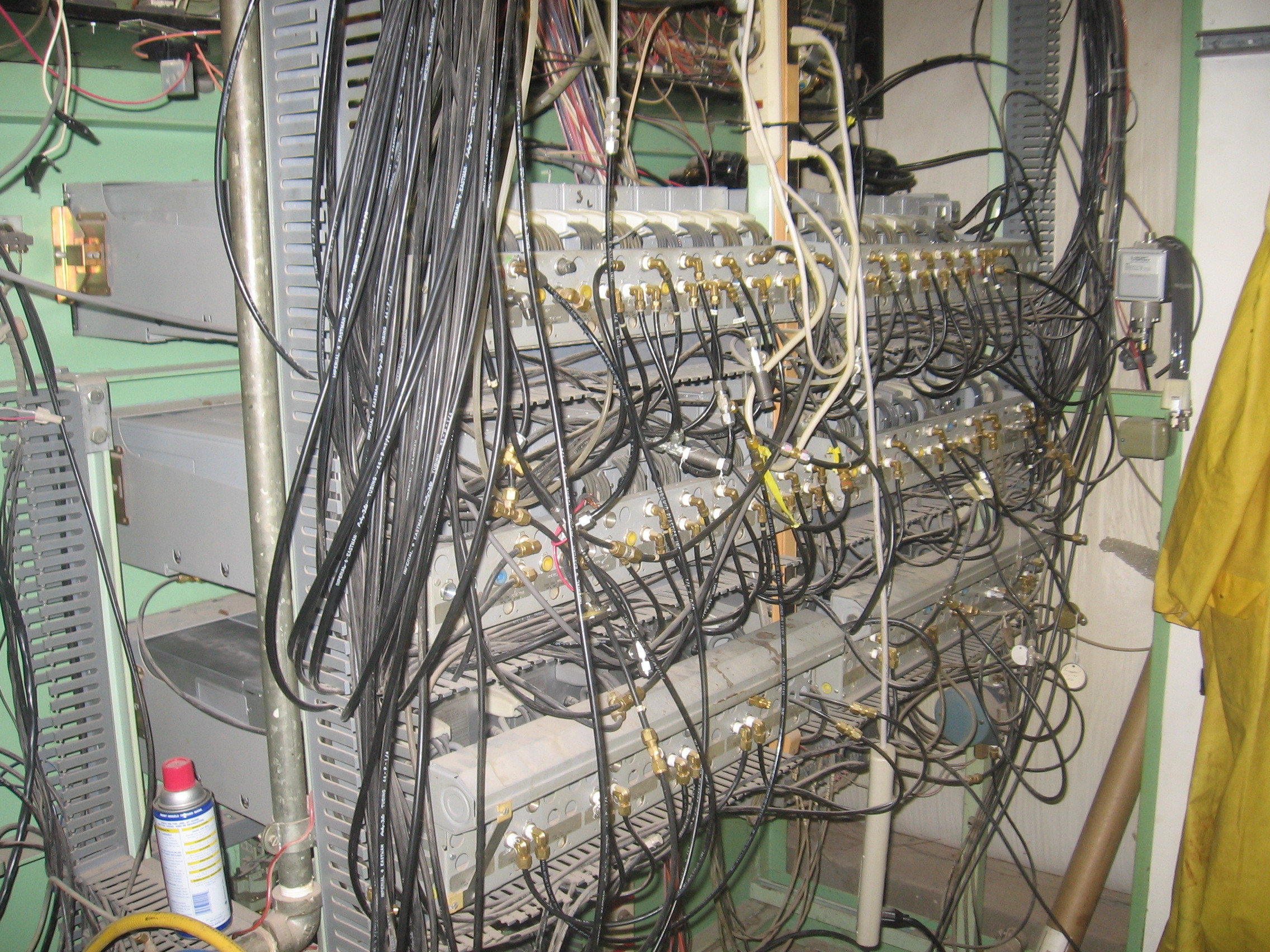

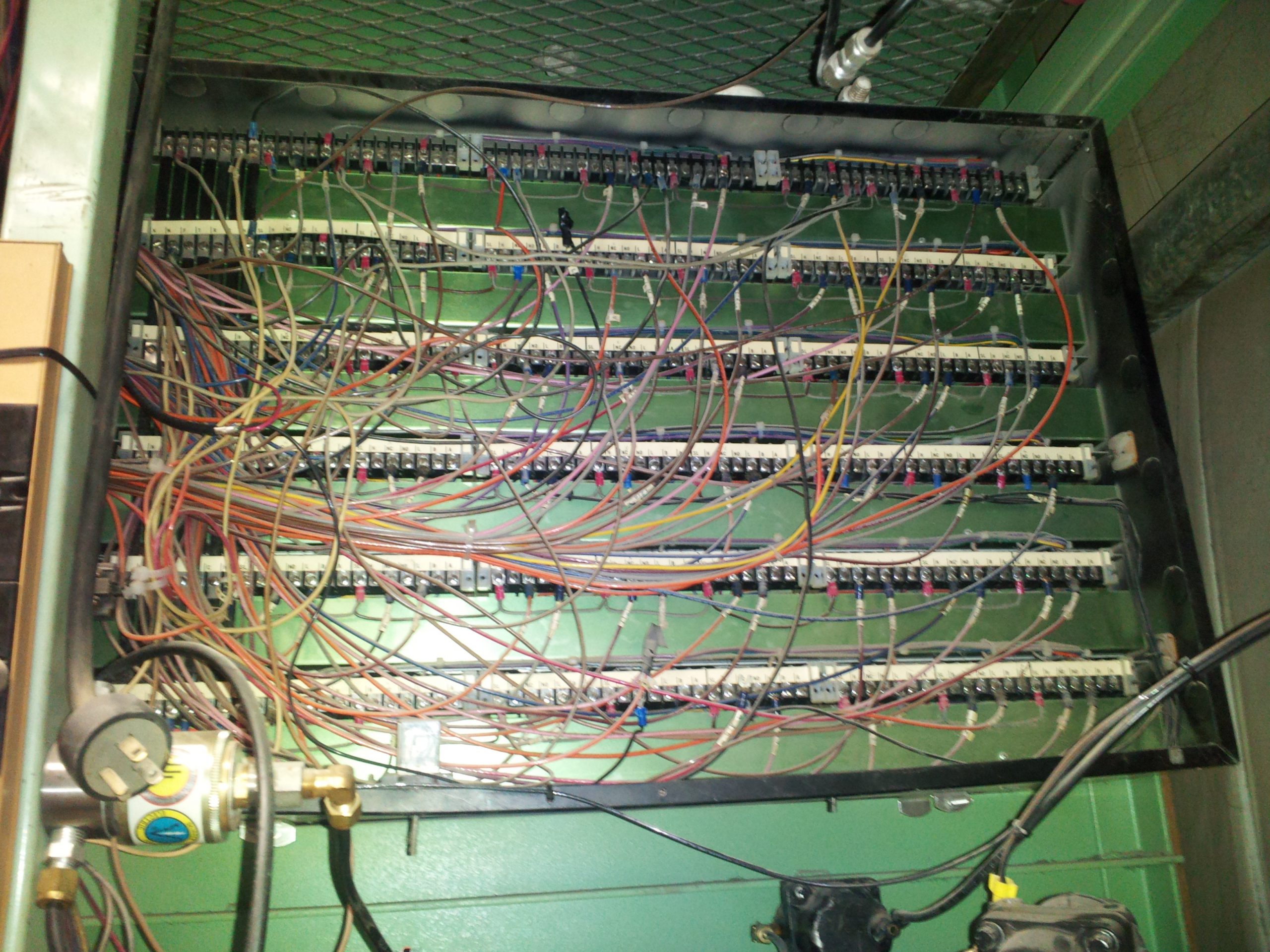

Existing control system consisted of local and panel mount pneumatic controllers and paper chart recorders that required extensive maintenance support and operator attendance. A requirement of the upgrade was to allow the work to be performed with minimal plant downtime.

Scope included:

- Engineering and Design of Control and Remote I/O panels

- Redundant Allen-Bradley ControlLogix controllers

- 4 Remote I/O Panels connected via redundant fiber loop

- Control Room, In Plant and Engineering HMI stations

- New instrumentation

- Replacement of 80 instruments

- Replacement of relay based alarm system

- Upgrade or replacement of control valves

- 40 control loops

- Valve sizing and trim confirmed

- PLC programing & FAT testing

- HMI design and historian management

- Comprehensive Fiber Optic Network Design

- Terminal Automation System for on and off loading of products

- Automated Load tickets

- Integration to Enterprise Accounting system

- Integration of gas chromatograph and gas measurement SCADA systems

- Turnkey upgrade implementation & construction support