Bakken Skid Design

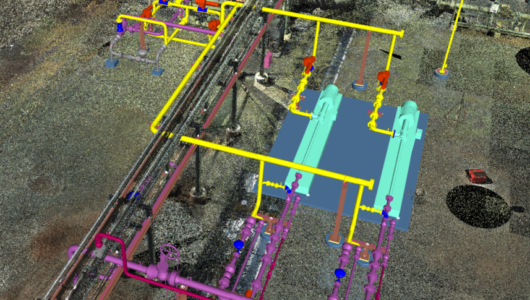

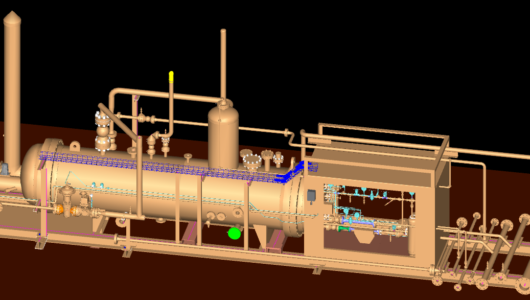

ZAP worked with our client and vendors to build equipment specifications and design documents for their standard well pad equipment and skids.

ZAP has executed over a 1,000 projects since 2001. Ensuring the success of your project is our primary objective.

ZAP worked with our client and vendors to build equipment specifications and design documents for their standard well pad equipment and skids.

An NGL Pipeline increased operating pressure to 1,440 psig and a client contracted ZAP to install new boost pumps to boost both Cryo plant 1 and plant 2 into the existing pipeline.

Standard Ammonia Skid Optimization ZAP assessed the hydraulic performance of the standard retail skid prototypes with the intention of determining what changes could optimize the truck loading capacity. ZAP ran simulations and aided in field testing and optimization which allowed customer to increase loading capacity to 150% of original capabilities. This increased sales revenue for […]

ZAP completed the EPC expansion of a New Mexico compressor station from 42MMSFD to 70MMSCFD and increased the discharge pressure from 700psig to 1250psig.

ZAP completed the engineering and design to modify an existing truck loadout system fed from a storage dome and from the F&I silo to meet Food Safety Modernization Act (FSMA) regulations.

ZAP was contracted to make a structural analysis of an existing four stage concrete preheater tower at a cement plant. Engineering services included developing a design basis and determining what load cases would be applied to the tower.

ZAP produced detailed engineering documentation, 3D models and component fabrication drawings for a client that wanted to create and own the separator design.

Plant maintenance requested improved access to a large duct’s slide gate above the roof level. A complex geometry was required to provide a platform that was supported by exterior building framing to avoid placing any load on existing roof trusses and yet account for operation of an adjacent roof hatch and maintain access to the slide gate components.

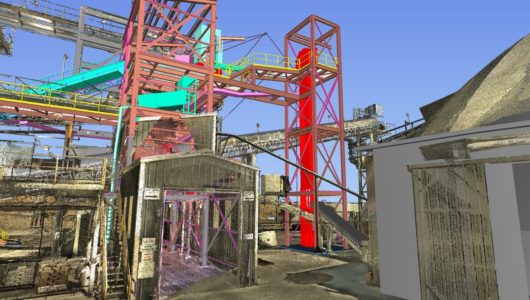

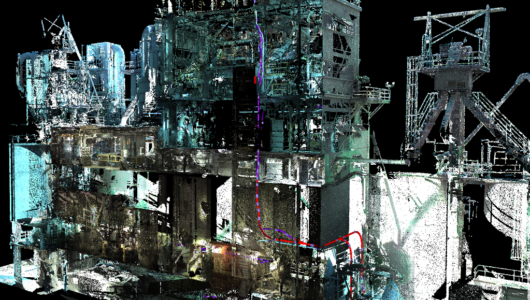

A steel manufacturer operates two 200-ton bridge cranes in their melt-shop for daily operations. For production and safety improvements they requested ZAP design fixed access platforms at each end of the building so that the cab operator could wash their own windshield periodically during shift. The original building had been modified and the original crane had been replaced since design drawings were produced. Our design efforts for this scope were complemented by a 3D scan of the facility for a higher confidence that our design had taken as-built conditions into account.

Central Vacuum System A manufacturing facility seeking to improve silica dust cleaning operations requested ZAP design a central vacuum system to cover critical areas of their seven-story crushing and screening building. For a more complex manifold layout through such a congested space, ZAP was able to provide a laser scan of the facility and design […]

A cement plant customer is planning to add equipment that will require new electrical cables for power, which will be supported by existing towers.

A manufacturing customer is replacing specialty transformers across many of their plants and the new model is heavier than the unit that had been installed before. The installation is taking place on the sixth floor of their production facility

During a plant outage, a cement customer found that their kiln lifting beam (or saddle) was buckling due to the compression forces between the kiln and the hydraulic cylinders used to lift the kiln off its trunnion rollers.

ZAP was contracted to modify an existing dome withdrawal system and convert the reclaim system from a mechanical auger to an aerated floor.

Excellence in Execution

ZAP is excited to announce the launch our expansion into the Eastern US with the addition of our East Coast Engineering office in Bethlehem, PA!

ZAP is excited to announce the launch our expansion into Houston, TX! We are thrilled to welcome Chris Combs who will assume the role of Vice President – Gulf Coast Engineering!