Dome Withdrawal Conversion

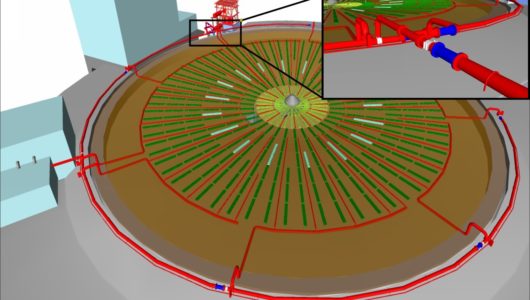

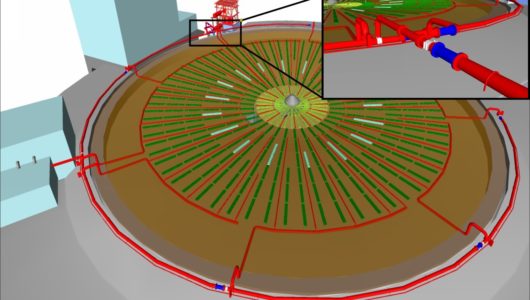

ZAP was contracted to modify an existing dome withdrawal system and convert the reclaim system from a mechanical auger to an aerated floor.

ZAP’s team members’ direct experience includes:

This operational experience, combined with engineering and project experience, enables ZAP to address the needs of our clients promptly and more accurately than our competition. ZAP is capable of various types and sizes of projects including balance-of-plant (BOP) engineering for large capital projects, mid-size capital projects such as distribution terminals and plant department upgrades, and smaller plant capital projects such as material handling and utility engineering.

ZAP was contracted to modify an existing dome withdrawal system and convert the reclaim system from a mechanical auger to an aerated floor.

During a plant outage, a cement customer found that their kiln lifting beam (or saddle) was buckling due to the compression forces between the kiln and the hydraulic cylinders used to lift the kiln off its trunnion rollers.

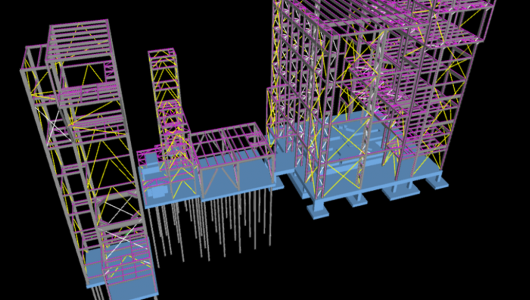

ZAP provided preliminary engineering and design for a vertical cement mill grinding system.

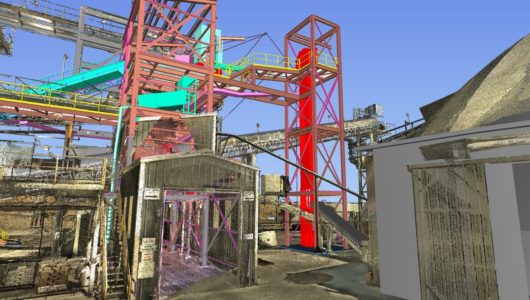

ZAP completed the engineering and design to modify an existing truck loadout system fed from a storage dome and from the F&I silo to meet Food Safety Modernization Act (FSMA) regulations.

Excellence in Execution

ZAP is excited to announce the launch our expansion into the Eastern US with the addition of our East Coast Engineering office in Bethlehem, PA!

ZAP is excited to announce the launch our expansion into Houston, TX! We are thrilled to welcome Chris Combs who will assume the role of Vice President – Gulf Coast Engineering!