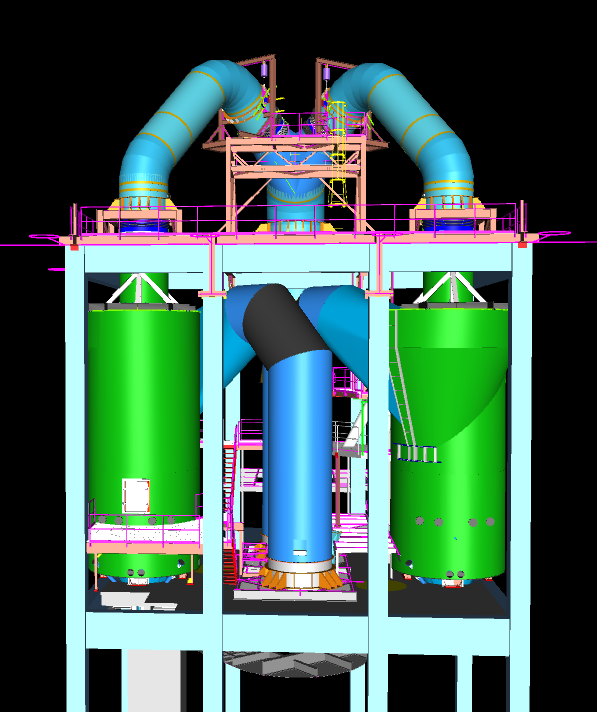

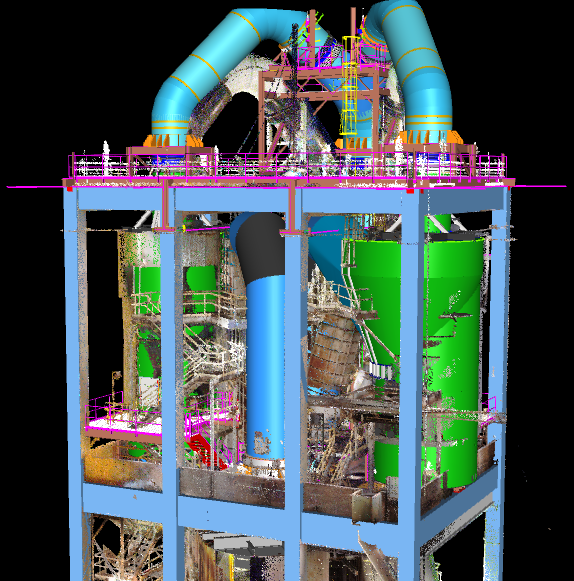

Cement Plant Preheater Tower Retrofit

ZAP was contracted to make a structural analysis of an existing four stage concrete preheater tower at a cement plant. Engineering services included developing a design basis and determining what load cases would be applied to the tower. ZAP identified all deficient areas. The client increased the scope to include structural reinforcing of the preheater to allow for additional loads of redesigned upper stage vessels, with refractory lining. ZAP completed all structural modification engineering & design, which included a shear wall for tower reinforcing, upper stage floor framing, modifications to existing concrete slab roof for removal and replacement of top vessels, duct structural supports, and tie points. ZAP performed a 3D scan of the tower for use in demo planning, vessel and duct replacement, tie-point definition, and platform engineering & design. ZAP designed the new structural supports in a skidded design, to allow for more work to take place in the shop and decrease the turnaround time, as this project was the critical path for the annual outage. ZAP coordinated with the client and construction contractor throughout outage planning, construction, and start up. ZAP only received 3 minor RFI’s during the entire construction process.